HACCP certification in the food sector:

let's be clear

The legislation is clear: all the procedures involved in the production and processing of food must strictly comply with the hygiene and safety requirements listed in the HACCP certification, the compass for all operators in the supply chain. The acronym stands for "Hazard Analysis and Critical Control Points". In summary, it is a safety protocol developed to guarantee food safety that arrives on the shelves of supermarkets and small shops, as well as on the tables of restaurants and clubs and school and industrial canteens. All operators must scrupulously, as well as compulsorily, respect the HACCP protocol, from the first steps of a new business, in particular during the design of the workplace. Facilities as well as machinery that come into contact with food must meet specific hygiene criteria.

Let's start from the story: the HACCP certification comes from space.

It’s got nothing to do with aliens, yet the history of HACCP certification begins in space. The system was indeed conceived in the 1960s in the United States with the aim of ensuring that the food supplied to NASA astronauts did not have any negative effect on their health, thus steming a concrete risk that could endanger missions in space. In Europe, and therefore also in Italy, the protocol was introduced in the 1990s, becoming mandatory for all food sector operators. Right after the legislation entered into force in 2006, the Danzi was definitively repealed and specific sanctions became applicable for those who do not follow the HACCP protocol to the letter. The scenario was far from limited: this is why, given the wide variety of food companies, products and procedures, the European Commission has drawn up guidelines to simplify the application of hygiene and food safety requirements according to HACCP certification.

Self-control and HACCP are not synonymous: the Ministry of Health explains it.

HACCP certification requires all operators in the so-called "post-primary" food sectors to draw up a "self-control plan", essentially a series of documents on food products safety to be made available to the control bodies during the inspection phase. This applies not only to the kitchens of restaurants, bars and public places, but also to dairies, wineries, breweries and slaughterhouses. In technical jargon, the "self-control plan" is called "manual" and must contain all the information relating to the hygiene and health plan adopted by the company on the basis of the HACCP system. But beware: the Ministry of Health makes it clear that the self-control system and HACCP system are not synonymous. The principle of the self-control system applies to all operators in the food chain, including primary sectors (cultivation, breeding, hunting and fishing), and results in the obligation to constantly monitor production procedures. HACCP, on the other hand, is the means that allows you to apply this principle in a rational and organized manner and is mandatory only for operators in the post-primary sectors. How? By identifying the critical points which, subjected to continuous monitoring, allow to control the risk of food contamination.

The 7 commandments of HACCP certification for food business operators.

To draw up the HACCP plan, the company must follow the seven principles of the protocol to identify the hazards and establish response actions to prevent and eliminate the risks regarding hygiene and food safety. The manual must also indicate, among other information, the definition of roles and responsibilities within the company, the description of the products, the type of food raw materials used and the employee training program. When it comes to HACCP, the risks that should be eliminated in terms of hygiene and safety are obviously those caused by chemical, physical or biological agents that compromise food safety. Contamination, indeed, is a danger that can occur during any phase of the food cycle, not only therefore in raw material processing, but also in the conservation, storage and distribution procedures. This is why rule number one for any activity in the food chain is a healthy and clean environment

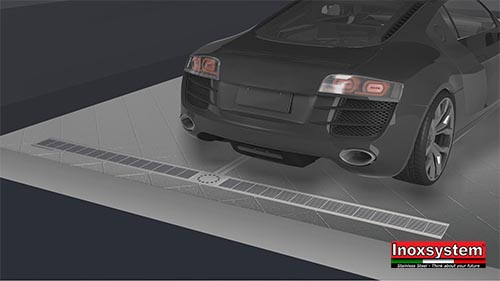

HACCP and floors: proper cleaning begins with planning.

Dreaming of starting your own business, perhaps a restaurant or a pub, immediately unleashes your imagination: elegant furnishing and the choice of the menu, just like in those fascinating design catalogs and starred restaurants advertisements. But even in the most trendy clubs "in the beginning it was the floor". “And all its accessories” we would add. Yes, because the cleaning procedures necessarily start from the base. During the processing of food raw materials in the kitchens, as well as in breweries, wineries, butcher’s shops and fish industry, food safety can be compromised by water, air, ground and animals. To minimize the risk of contamination, the HACCP certification specifies that food industry facilities must be designed to permit adequate maintenance, cleaning and disinfection. And it goes into detail, pointing out that the accumulation of dirt, contact with toxic materials, condensation, the shedding of particles into food and the formation of or undesirable mold on surfaces must be prevented.

Can floors be HACCP certified?

There is no certification, but what can be done, or rather must be done, is to design a floor that meets the hygienic requirements of the HACCP certification. Floor drainage systems are essential to get maximum hygiene with minimum effort. Food safety rules clearly state that floors and walls surfaces in food industry facilities must be smooth, compact and easily washable and disinfectable. In particular, the floors can be made of different materials, but they must be rigorously designed to prevent any stagnation of water. And, where high volumes of water are used during food production and processing stages, floors must be sloped sufficiently to convey surface water into drainage systems (channels and floor drains).

Can drainage systems be HACCP certified?

Let's be clear: HACCP certification is not a “product certification”, and this is good to know before designing your own workplace. It is, instead, a certificate that can be obtained by attending a specific course designed specifically for food industry operators. This certificate “certifies” knowledge of food hygiene requirements, from microbiology to food preservation, from the sanitation procedures in food processing facilities to national and European legislation. There are no floors with HACCP certification, just like there are no HACCP certified drainage systems. Yet, drainage systems manufacturers can design gratings, floor drains and channels according to HACCP protocol guidelines, thus offering products that ensure high hygienic performance. Inoxsystem® Total Hygenic line strictly follows the directives concerning hygiene in the workplace. Thanks to a product entirely made of stainless steel, to a grating without perimeter borders and to the completely removable odor trap, a thorough cleaning of the drainage systems is easily done. Furthermore, by purchasing an Inoxsystem® Total Hygienic branded product, the company provides you with a certificate that guarantees the products’ functionality and a guidance on the cleaning procedures to be followed in order to comply with the existing HACCP regulations. With this certificate combined with your manual, you can sleep easy knowing that you have chosen the ideal solution where hygiene is essential. And your customers, and employees, will thank you.