Drainage system: to each their own. Which one to choose?

An effective drainage system, whether internal or external, allows water to be collected through systems designed to support its natural cycle, facilitating its flow and avoiding possible stagnation

Gutters, manholes, drain grates and sumps. Let's look at the main components of drainage systems

Avoiding stagnation and flooding and preventing infiltration: the value of a drainage system also emerges in the house, from terraces to garages

In the food and beverage industry, drainage systems actively contribute to prevent microbiological hazards during food processing

Wineries, breweries, and oil mills: efficient management of the considerable amounts of water involved in production requires a calibrated and effective drainage system.

In the pharmaceutical industry, the design of a sterile environment starts from the floor. The drainage system must ensure optimal water management, preventing the introduction of dirt or bacteria into the environment.

The weight of water While water is a valuable commodity, it can also turn into a problem if not managed carefully. This applies both at house and in the professional field: ensuring proper water drainage and dry environments is crucial. In a nutshell, it is a matter of creating rainwater collection and washing systems that support its natural cycle, facilitating its flow and avoiding possible stagnation. Let us explore the different types of drainage systems, analysing which are the most suitable solutions in some of the main scenarios How a drainage system works Indoor or outdoor water management is a key element to be considered both during the design phase and during the life of a building. The drainage system takes an active role in artificially supporting the normal water cycle, preventing stagnation and flooding.

External drainage systems take care of rainwater runoff, directing it towards collection basins. These types of systems are essential on terraces, pavements, forecourts and even swimming pool edges, where water needs to drain away so as not to cause damage to the structure. The main components are sumps, gutters and drain grates.

Internal drainage systems, on the other hand, are designed to manage water runoff inside buildings or houses. In addition to the residential sector, there are many sectors that require them: from the food industry (wineries, breweries, corn, and oil production) to the pharmaceutical industry, where sterility and safety are essential. Also in this case, drainage takes place using gutters, grates and siphoned manholes

How a drainage system is composed Both macro types of drainage systems, external and internal, are made up of various components. Each of them plays a decisive role in proper water management.

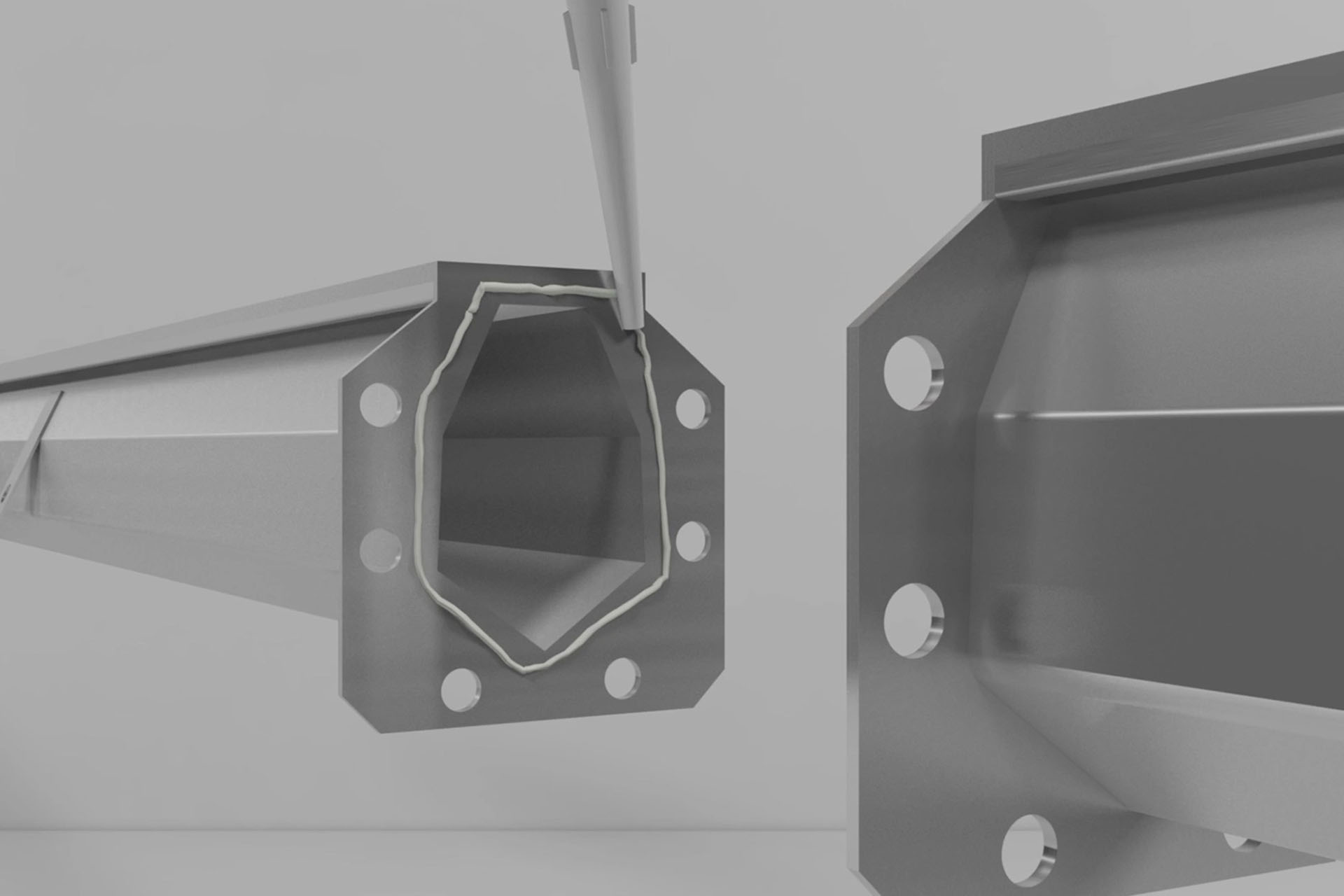

Drainage channels are the heart of drainage systems. Their function is to direct water towards the drainage manholes, thus ensuring regulated runoff. Thanks to their internal gradient, in fact, gutters allow water to flow towards the collection point and, being both long and, albeit partially, deep, they ensure proper flow and easier maintenance.

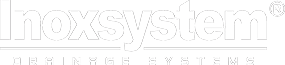

Manholes, also referred to as gullies, are used for draining water. There are different types and shapes that can be combined with gullies to construct a customised drainage system.

Drain grates are placed at the top of the channels, making the drainage system not only driveable and walkable, but also protecting it from foreign bodies that could clog it and facilitating manual inspection.

Anti-odour siphons, placed inside manholes and sumps, block odours inside pipes.

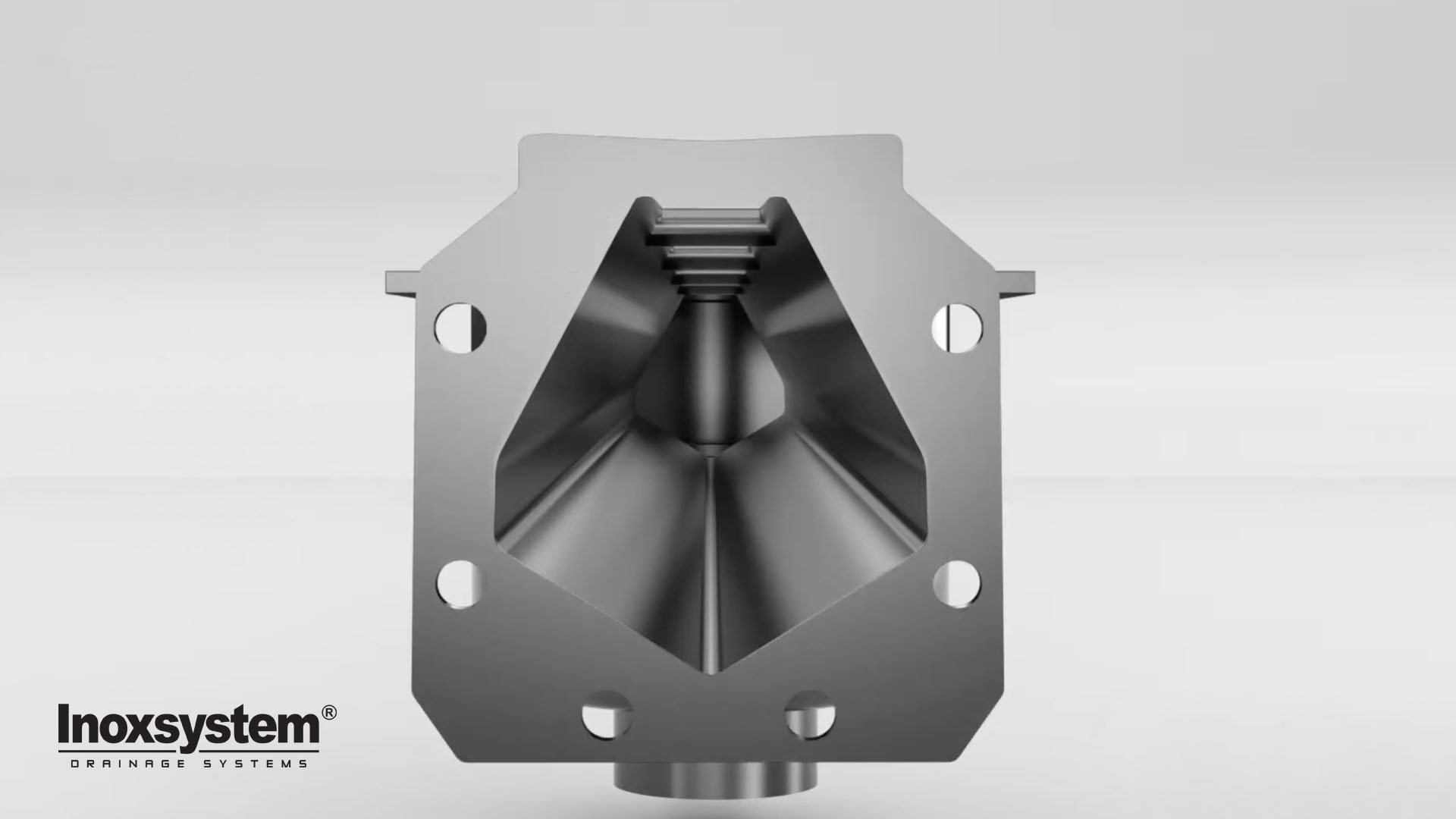

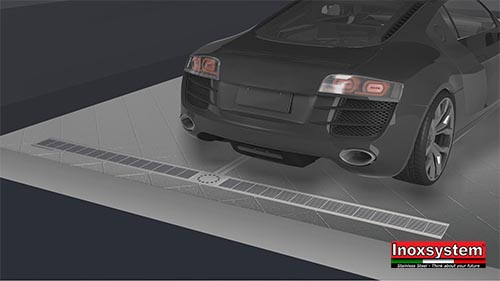

In addition to standard solutions, Inoxsystem® offers tailor-made products to meet the specific needs of each customer. Discover our range of products From showers, to the terrace all the way to the garage: how to keep a house dry Ensuring dry and healthy environments is a priority in the house. The focus is on showers, terraces, and garages in particular. To avoid stagnation and flooding, an efficient drainage system for rainwater and washing water management is essential. In the case of terraces, it is advisable to install stainless steel slotted/slotted gutters and manhole covers. These elements are highly driveable, durable and not visible on the pavement. In addition, to prevent further infiltration, Inoxsystem® recommends the use of a protective sheathing and, therefore, drainage products with a perimeter sheathing edge to create a seamless surface. The use of sheathing is not just an aesthetic choice; on the contrary, it is a fundamental element that prevents infiltration into the screed in the event of cracks forming in the floor. In underground garages, however, drainage systems require effective design or correction to solve the problem of water run-off. For this purpose, the installation of plate manholes or stainless steel slotted/slotted gullies are the best solution. They ensure strength to withstand heavy loads, durability and ease of maintenance. Thanks to a special resin inserted under the edges of the channel, in fact, Inoxsystem® is able to certify its products in resistance class D400

READ ALSO: Underground garage: how to avoid flooding Drainage in food environments: safety and hygiene The (right) drainage system is of primary importance in environments with a high risk of contamination. It actively contributes to preventing microbiological hazards during the handling of foodstuffs such as meat and fish.

In this respect, Inoxsystem® offers advanced drainage systems that contribute to maintaining the standards required to protect consumer health, guaranteeing product quality and creating a safe working environment. Specifically, it proposes solutions in stainless steel, a material that allows the hygienisation of environments according to the principles of the HACCP protocol, where the Inoxsystem® Total Hygienic line, designed, precisely, to follow all the directives of the European Commission, is particularly important. This commitment also extends to factories where fruit and vegetables are processed. Here, continuous food washing generates wet floors that require constant drainage. The ideal choice for maintaining healthy environments and ensuring corrosion resistance is the application of slotted or grating systems made of stainless steel.

The same principle applies to drainage systems in the fishing industry, where the use of water during processes imposes the need for effective drainage systems. On this front, Inoxsystem® adapts to the specific needs of the sector with tailor-made solutions in AISI 304 or AISI 316L stainless steel, the latter resistant to salt corrosion (as well as chlorine and aggressive acids). Furthermore, as highlighted in a previous article, floors in fish factories not only have to cope with large quantities of water, but also with the presence of solid residues. Drainage systems must be designed to facilitate the cleaning of gutters and manholes, thus avoiding potential sources of contamination.

READ ALSO: Inoxsystem® Total Hygienic: a new ally for floor cleaning Drainage systems for wineries, breweries and mineral water plants Food safety is also a top priority in environments such as wineries, breweries, oil mills and mineral water plants. Efficient management of the considerable amounts of water involved in production requires an effective drainage system. It's not just a matter of having a safe and compliant environment, but being able to count on an ally that simplifies sanitation operations. The choice of material falls, again, on AISI 304 or AISI 316L stainless steel, which can offer resistance to heavy loads and maximum hygienic performance. For these environments, we recommend the installation of removable gratings without perimeter edging from the Inoxsystem® Total Hygienic line, which can be adapted to the customer's different needs.

For their part, oil mills need to handle semi-humid surfaces with a high risk of slipping. In this case, it is advisable to install a drainage system consisting of protective gratings with a surface indentation that guarantees slip resistance. Even in mineral water bottling plants, stainless steel proves to be the material of choice throughout the entire water course. Water pipes, tanks and drainage systems play a decisive role in preserving the hygiene and purity of water. Ensuring sterility and safety in the pharmaceutical industry Finally, a glance at the pharmaceutical industry, where the sterilisation of environments, particularly 'clean rooms', is essential. In this sense, the design of a sterile environment starts from the floor. The drainage system must ensure optimal water management by preventing the introduction of dirt or bacteria into the environment. For this reason, Inoxsystem® recommends the application of stainless-steel manhole covers that can be fitted with a blind cover with an O-ring seal. In these particular cases, drainage systems made of AISI 316L stainless steel, which is even more high-performance than 304, are usually required. This material, in fact, guarantees maximum resistance to corrosion and substances such as chlorides, while maintaining the standards of purity and safety required in the pharmaceutical sector. In the case of linoleum flooring, a material commonly used in clean rooms, Inoxsystem® provides a perimeter 'PVC door' frame. This seamless integration between flooring and drainage creates an effective barrier against germs and bacteria. In addition, room cleaning operations are simplified thanks to the installation of manholes and channels with internal radiused corners and fully removable siphon and basket kits. Discover our range of products Request more information Name Surname Email * Please fill in the required fields. Phone Company Subject Please fill in the required fields. QmxvZzogRHJhaW5hZ2Ugc3lzdGVtOiB0byBlYWNoIHRoZWlyIG93bi4gV2hpY2ggb25lIHRvIGNob29zZT8KPHA+PHN0cm9uZz5EYTo8L3N0cm9uZz57e2ZpcnN0LW5hbWV9fSB7e2xhc3QtbmFtZX19PC9wPgo8cD48c3Ryb25nPkVtYWlsOjwvc3Ryb25nPnt7ZW1haWx9fTwvcD4KPHA+PHN0cm9uZz5PZ2dldHRvOjwvc3Ryb25nPnt7c3ViamVjdH19PC9wPgo8cD48c3Ryb25nPkF6aWVuZGE6PC9zdHJvbmc+e3themllbmRhfX08L3A+CjxwPjxzdHJvbmc+VGVsZWZvbm86PC9zdHJvbmc+e3twaG9uZX19PC9wPgo8cD48c3Ryb25nPk1lc3NhZ2dpbzo8L3N0cm9uZz57e21lc3NhZ2V9fTwvcD4= I accept the Privacy Send Message More from the blog